REINFORCED METAL LINK STABILIZERS

ENHANCED STRENGTH WHERE IT MATTERS MOST

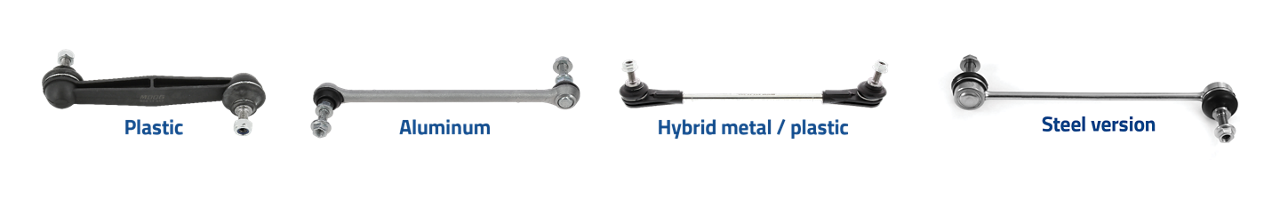

As vehicle manufacturers move toward lighter materials, many link stabilizers are now made of plastic, aluminum, or hybrid (metal/plastic) materials. While these OE parts perform well under normal conditions, challenging road environments can push them to their limits — leading to premature failure and unnecessary workshop downtime.

That’s where MOOG makes the difference. Rooted in our problem-solving philosophy, we offer reinforced metal link stabilizers that go beyond standard OE design — delivering superior durability and reliability, ensuring a longer service life for your customers and reducing costly returns.

MOOG understands that every repair is different — that’s why we offer both reinforced steel stabilizers for added strength and OE-like versions for standard replacements. This flexibility ensures installers can choose the best fit for each job, keeping vehicles roadworthy and compliant with inspection standards.

WHY CHOOSE MOOG'S REINFORCED METAL LINK STABILIZERS?

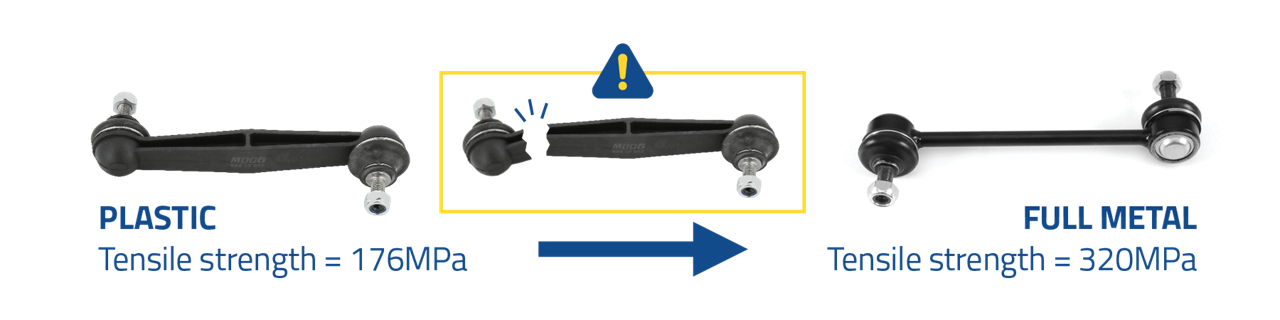

Engineered for Tougher Conditions

MOOG's reinforced metal link stabilizers are engineered with enhanced mechanical properties, designed to withstand potholes, curbs, and rough roads. Reinforced metal link stabilizers reduce the risk of part failure — helping you prevent costly comebacks.

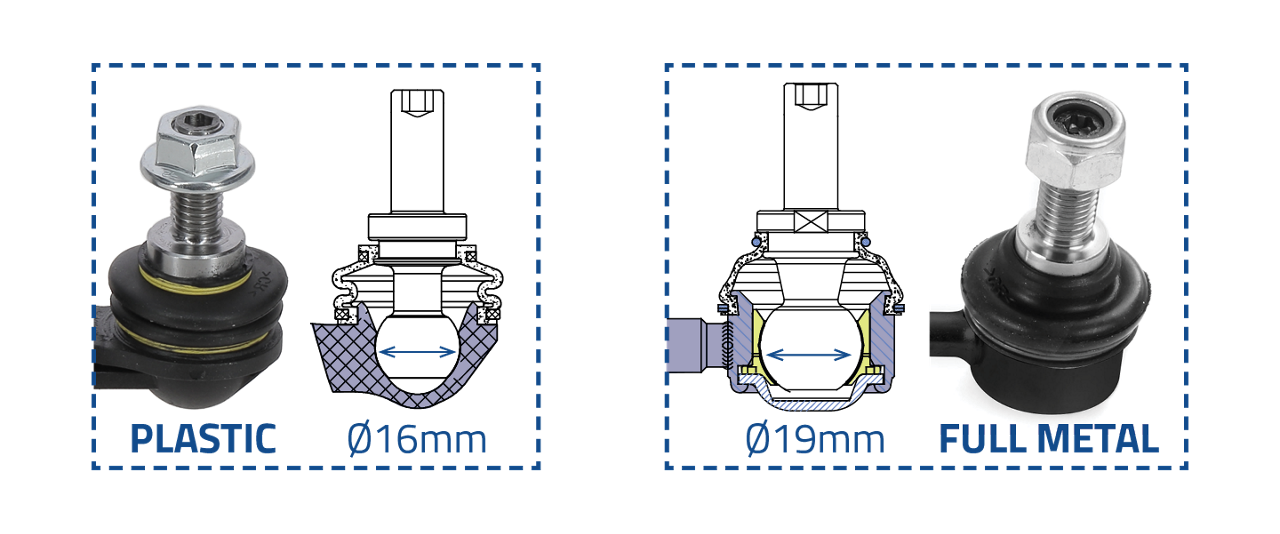

LARGER BALL DIAMETER FOR EXTENDED LIFESPAN

A larger ball diameter compared to plastic or aluminum alternatives ensures better load distribution, reducing wear and increasing durability.

PRECISION POM BEARING FOR SMOOTHER PERFORMANCE

Unlike hybrid or plastic designs, our reinforced metal link stabilizers feature a dedicated Polyoxymethylene (POM) bearing, improving longevity and reducing friction for smoother operation.

PLASTIC, ALUMINUM, HYBRID AND FULL METAL LINK STABILIZER COMPARISON

| PLASTIC | ALUMINUM | HYBRID | FULL METAL | |

| Resistance to normal driving conditions | + | + | + | ++ |

| Resistance to extreme driving conditions | -- | - | - | + |

| Durability | +/- | +/- | +/- | ++ |

| OE-alike design | + | + | + | - |

| Can be individually replaced | + | + | + | - |

TENSILE STRENGTH AND BALL DIAMETER COMPARATIVE ANALYSIS

STAY COMPLIANT WITH EUROPEAN VEHICLE INSPECTIONS

When replacing stabilizer links, consistency in material and technology is critical — especially in regions where periodic technical inspections are mandated by European regulations. Unlike standard OE designs, MOOG’s full-metal link stabilizers feature a distinct engineering approach that enhances durability and performance. However, due to these design differences, mixing different materials or technologies on the same axle is not recommended.

Here’s why this matters: inspection compliance is crucial, as many European governments require vehicle suspension systems to be symmetrical and balanced. If different stabilizer types are installed on each side of the axle, it can cause discrepancies in handling characteristics, leading to potential rejection during periodic technical inspections. Beyond compliance, maintaining performance consistency is essential — stabilizer links work in pairs to ensure vehicle stability, and uneven materials or designs can result in asymmetrical suspension response, reducing handling precision and ride quality. Additionally, using mismatched link stabilizers may lead to premature wear on one side, increasing the risk of customer complaints, warranty claims, or repeat repairs.

MOOG provides the solution. To ensure compliance and optimal performance, our reinforced metal link stabilizers must always be replaced in pairs. Additionally, we recognize that mechanics have different preferences and vehicle needs—so MOOG offers both stronger steel alternatives (designated with an 'M') and OE-like versions in the product range. This flexibility allows installers to choose the best solution for each repair while ensuring vehicles remain roadworthy under regulatory inspections.

MOOG STEEL ALTERNATIVE RANGE

MOST POPULAR PART NUMBERS

| MOOG ORIGINAL REFERENCE | MOOG ORIGINAL MATERIAL | MOOG STEEL ALTERNATIVE | MAKE | MODELS | POSITION |

| AL-LS-7542 | Plastic | AL-LS-7542M | ALFA ROMEO | 147, 156, GT | Rear axle Left & Right |

| BM-LS-10919 | Plastic | BM-LS-10919M | BMW | 1, 2, 3, 4, i8, X1 |

Rear axle Left |

| BM-LS-10920 | Plastic | BM-LS-10920M | BMW | 1, 2, 3, 4, i8, X1 |

Rear axle Right |

| BM-LS-14782 | Hybrid | BM-LS-14782M | MINI | MINI | Front axle Left & Right |

| BM-LS-8845 | Plastic | BM-LS-8845M | BMW | 5, 6 | Rear axle Left & Right |

| ME-LS-10471 | Aluminum | ME-LS-10471M | MERCEDES-BENZ | CLS, E-CLASS | Front axle Left |

| ME-LS-10472 | Aluminum | ME-LS-10472M | MERCEDES-BENZ |

CLS, E-CLASS |

Front axle Right |

| NI-LS-12697 | Aluminum | NI-LS-12697M | NISSAN | CUBE, MICRA, NOTE, NV200 | Front axle Left & Right |

| RE-LS-15514 | Aluminum | RE-LS-15514M | RENAULT | ESPACE, MEGANE, SCÉNIC, TALISMAN | Front axle Left & Right |

| RE-LS-7999 | Aluminum | RE-LS-7999M | RENAULT | MEGANE, SCÉNIC | Front axle Left & Right |

CHOOSE STRENGTH.

CHOOSE MOOG.

At MOOG, we don’t just make parts—we create solutions that address real challenges in the workshop. Every product we make is designed, tested, and manufactured to help you, the installer, work smarter, faster, and with confidence. On top, each MOOG Steering and Suspension product is backed up by our new 5-year warranty.

Discover more about MOOG's products >

Discover more about 5-year warranty >

OTHER MOOG PROBLEM SOLVING FEATURES

THE PROBLEM SOLVER

We make the job easier by making our products better. This is how MOOG has earned its reputation as the chassis industry’s problem solver for 100 years: by constantly introducing design enhancements that extend product life and simplify installation and replacement.

REMARKEABLE QUALITY:

5-YEAR WARRANTY

Each MOOG Steering and Suspension product is tested to the highest standars, worthy of the MOOG name and backed up by our new 5-year warranty.