WHY HARDEN BALL PINS ARE USED WITH CARBON FIBRE BEARINGS?

DID YOU KNOW: ADVICE FOR THE PROFESSIONAL

Vehicle manufacturers sometimes harden ball pins for applications where the ball pin neck can be subjected to very high forces e.g. high speed braking or where the vehicle can be heavily loaded. Hardening increases fatigue resistance and increases durability.

INDUCTION HARDENING

Induction hardening is one of the most efficient ways of hardening steels. A process of substantial heating (by passing a high current and voltage through the metal) followed by immediate cooling, makes the steel significantly harder. As MOOG matches or exceeds OE specifications, such hardening is applied wherever vehicle manufacturers deploy it. As a further step, MOOG’s Hybrid Core innovation applies induction hardening to all ball pins used in conjunction with its patented carbon fibre bearing.

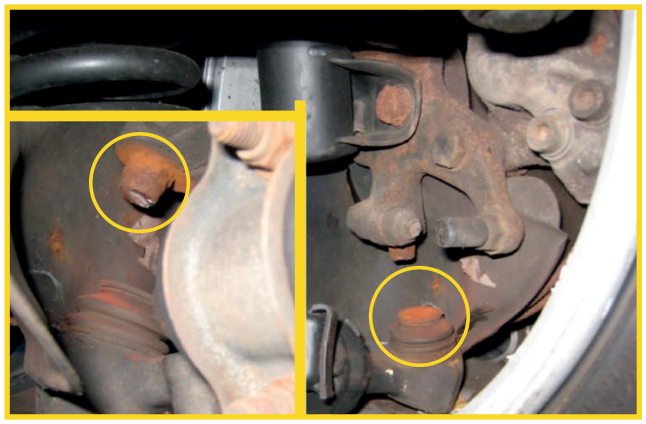

The carbon fibre technology of MOOG bearings dramatically increases the performance and durability of ball joints which now last much longer. It follows that the weakest area that is clearly with the bearing on competitor parts is now transferred to ball pin neck for MOOG ball joints. To accommodate this, the ball pin has also been strengthened.

A fatigue failure of a ball pin neck can cause a driver to lose control of the vehicle. The combination of an induction hardened ball pin neck and MOOG’s patented carbon fibre bearing not only enhances both the performance and the service life of the ball joint but also improves driver safety.

This commitment to product quality and innovation is what separates MOOG from the competition.

The content contained in this article is for entertainment and informational purposes only and should not be used in lieu of seeking professional advice from a certified technician or mechanic. We encourage you to consult with a certified technician or mechanic if you have specific questions or concerns relating to any of the topics covered herein. Under no circumstances will we be liable for any loss or damage caused by your reliance on any content.

OTHER INSTALLATION TIPS

THE PROBLEM SOLVER

We make the job easier by making our products better. This is how MOOG has earned its reputation as the chassis industry’s problem solver for 100 years: by constantly introducing design enhancements that extend product life and simplify installation and replacement.

REMARKEABLE QUALITY:

5-YEAR WARRANTY

Each MOOG Steering and Suspension product is tested to the highest standars, worthy of the MOOG name and backed up by our new 5-year warranty.