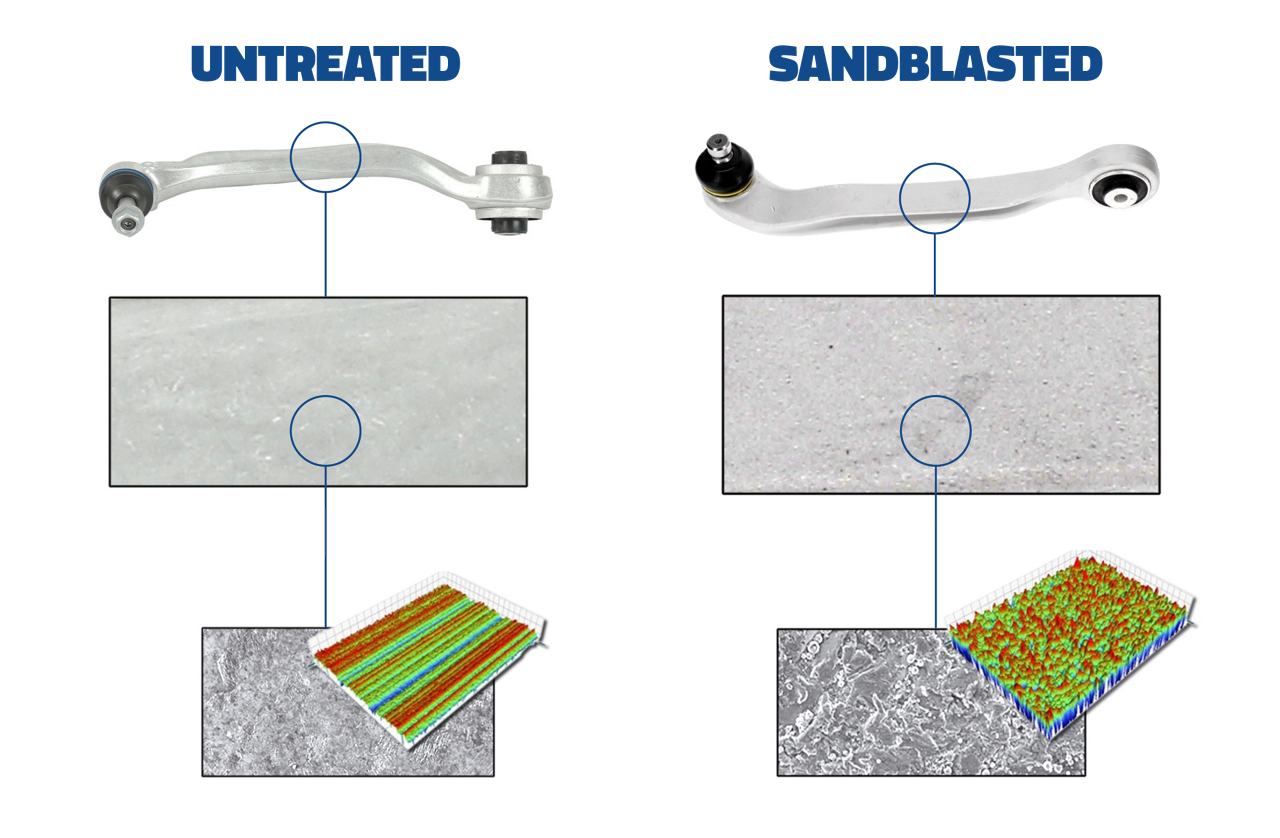

SANDBLASTED TREATMENT FOR INCREASED STRENGTH

STRONGER. SAFER. ENGINEERED TO LAST.

When it comes to suspension repairs, installers need solutions, not just parts. That’s why MOOG applies its Problem-Solver Philosophy to every product. MOOG’s light-weight aluminum track control arms undergo an advanced sandblasting treatment to eliminate micro-cracks and significantly enhance fatigue strength by up to 40%.

SANDBLASTING:

WHY IT MATTERS

MOOG’s light-weight aluminum track control arms are sandblasted to remove micro-cracks making the arms stronger and safer. Sandblasting treatment provides a high-end consistent surface finish and forms a hardened layer on the surface of the aluminum arm body, eliminating micro cracks and increasing fatigue strength by up to 40%. The hardening of the sandblasted surface retards the crack nucleation, enhances the resistance to permanent deformation and improves the stress distribution, thus avoiding crack propagation.

The sandblasting treatment removes visible imperfections caused by molding, cavities, or handling impacts, resulting in a smooth and uniform surface finish.

Moulding, machining, transporting or assembling an aluminium arm body inevitably creates stress concentrated micro-regions, or even cracks on the surface or interior structure. Similar structural damages can also be caused by impact while a vehicle is in operation. Sandblasting forms a hardened layer on the surface of the aluminium arm body, increasing fatigue strength by up to 40%. The surface roughness and hardening resulting from sandblasting increases resistance to fatigue cracking. This type of cracking usually starts at the surface of the material. Sandblasting plays an important role in delaying its initiation and hindering its propagation.

WHY STRENGTH MATTERS:

PREVENTING CRITICAL FAILURES

Weak or poorly treated metal components in steering and suspension systems are prone to premature failure, leading to safety risks and costly repairs. Below an example of a common failure that can occur when components lack proper material hardening and durability:

Control arm housing failure – A brittle or poorly manufactured housing can crack under load, leading to instability and potentially losing control over the vehicle.

CHOOSE STRENGTH.

CHOOSE MOOG.

At MOOG, we don’t just make parts—we create solutions that address real challenges in the workshop. Every product we make is designed, tested, and manufactured to help you, the installer, work smarter, faster, and with confidence. On top, each MOOG Steering and Suspension product is backed up by our new 5-year warranty.

Discover more about MOOG's products >

Discover more about 5-year warranty >

OTHER MOOG PROBLEM SOLVING FEATURES

THE PROBLEM SOLVER

We make the job easier by making our products better. This is how MOOG has earned its reputation as the chassis industry’s problem solver for 100 years: by constantly introducing design enhancements that extend product life and simplify installation and replacement.

REMARKEABLE QUALITY:

5-YEAR WARRANTY

Each MOOG Steering and Suspension product is tested to the highest standars, worthy of the MOOG name and backed up by our new 5-year warranty.