wheel end bearings

endurance/durability testing

DID YOU KNOW: ADVICE FOR THE PROFESSIONAL

OVERVIEW

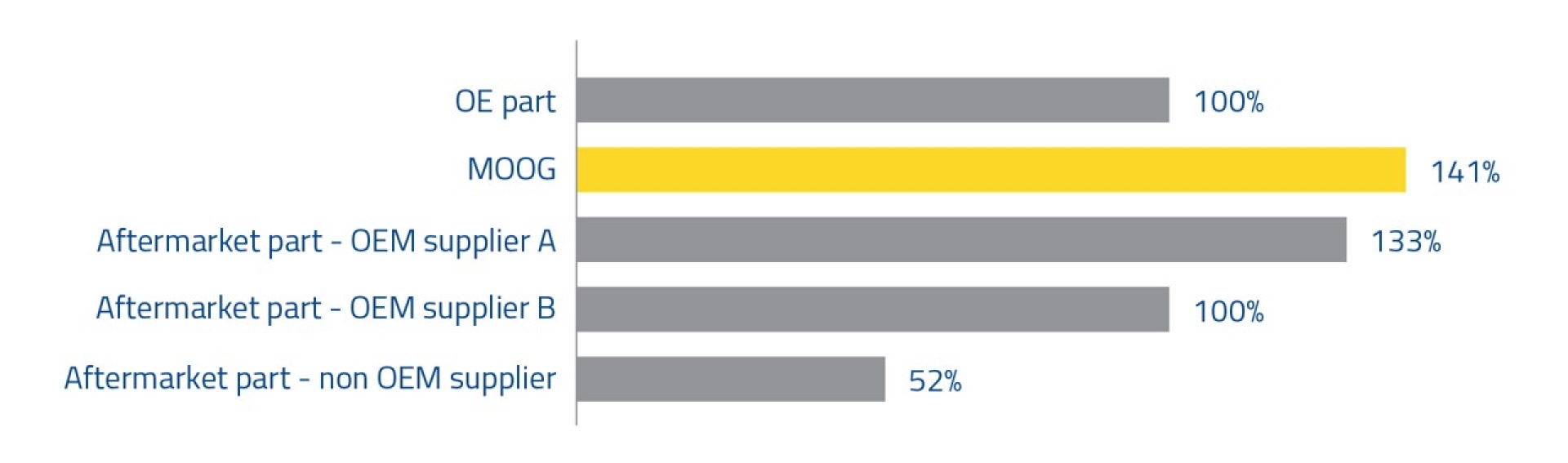

The highest load supported by a wheel end bearing, occurs while the vehicle is cornering, since part of the vehicle weight is shifted to the wheels opposite to cornering direction, dramatically increasing axial and radial forces at that location. In partnership with IAMT*, MOOG has simulated forces faced by a wheel end bearing fitted to a vehicle driving at a constant speed of 80km/h on a circular track of 120m and 80m of radius, allowing it to reach respectively an acceleration of 0,4g and 0,6g. (1)

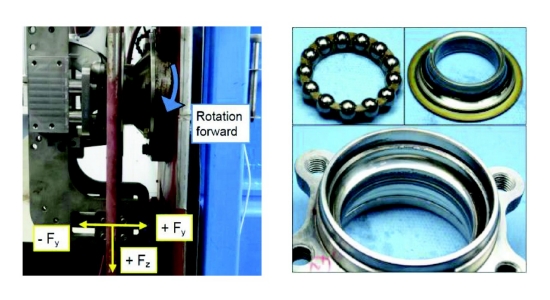

(2) Both axial and radial loads (Fy and Fz) are calculated for each tested vehicle (based on its weight, speed and track radius, ...) and replicated (3) on the testing bench, at the exact location where they are initiated (i.e. at the point of contact between the tire and the road, meaning that wheel radius (Rdyn) and rim offset (Et) are also taken on board in the simulatuion).

Example of durability / endurance testing conducted on front left bearing of Audi A3 (MOOG Ref VO-WB-11019):

Phase 1: 7.260 N (radial) / 2.900 N (axial)

Phase 2: 8.930 N (radial) / 7.150 N (axial)

Et = 45 mm

Rdyn = 314 mm

Rotation speed = 700 rpm (+/- 80 km/h)

- All other fitted parts (wheel knuckle, brake disc, ...) are OEM references

- All bolts and nuts were tightened to the torque values recommended by the car manufacturer

- Monitored parameters included bearing temperature, amplitude/frequency of bearing vibrations, bearing clearance and bearing acceleration (torque required to maintain 700rpm). These parameters were used to rank each sample.

The content contained in this article is for entertainment and informational purposes only and should not be used in lieu of seeking professional advice from a certified technician or mechanic. We encourage you to consult with a certified technician or mechanic if you have specific questions or concerns relating to any of the topics covered herein. Under no circumstances will we be liable for any loss or damage caused by your reliance on any content.

*Data provided in conjuction with IAMT Engineering, a globally recognised chassis systems testing and development organisation.

OTHER INSTALLATION TIPS

THE PROBLEM SOLVER

We make the job easier by making our products better. This is how MOOG has earned its reputation as the chassis industry’s problem solver for 100 years: by constantly introducing design enhancements that extend product life and simplify installation and replacement.

REMARKEABLE QUALITY:

5-YEAR WARRANTY

Each MOOG Steering and Suspension product is tested to the highest standars, worthy of the MOOG name and backed up by our new 5-year warranty.